In fully automated manufacturing processes, operators are protected from any hazardous machine movements by guards such as safety gates or safety bonnets.

However, how can this protection be maintained in the event of maintenance? How is the employee protected when the machine needs to be repaired or cleaned? When and how may the operator deliberately override the protective devices?

This is where BERNSTEIN’s three-stage enabling foot switches come into play. Because the answer to these questions is enabling function.

Topic overview

1. What is meant by "enable function"?

1.2. Two-step and three-step enabling function

1.3. Function of a three-stage enabling foot switch

2. How does a three-stage enabling foot switch work?

2.2. So why does it make sense to use your foot?

2.3. Areas of use of the foot switches

3. What are the advantages of BERNSTEIN foot switches with enabling function?

What is meant by "enable function"?

The enabling function has been a proven function for many years and has also been part of various standards for a long time, such as EN ISO 12100. This standard deals with the safety of machines and describes the enabling function as: “Additional manually operated device used in conjunction with a start-up control which, when continuously actuated, allows the machine to function”.

The regulations state that when the safety fence is open, machine operation is prevented by a door interlock. During manual operation, when the operator approaches the machine during programming, maintenance or test runs, the danger must be reduced by means of various measures.

This includes slow machine operation (reduction of kinetic energy) and restriction of the moving part of the machine. Measures must also be taken to be able to stop the machine in an emergency.

Such safety measures include the use of enabling switches. However, no movement may be started by actuating the enabling switch alone. The movement is only permitted by and must be initiated by means of a separate start control. This is prescribed, for example, by EN 60204-1, which also deals with the safety of machines.

Two-step and three-step enabling function

In essence, enabling switches are divided into two and three-stage variants. The two-stage types are now obsolete and are only used in old machines.

For new products, for example, EN ISO 10218-1 (safety requirements for industrial robots) prescribes three-stage enabling switches.

Function of a three-stage enabling foot switch

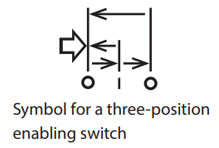

A three-stage enabling switch must have the following basic switching stages:

- In the idle state (level 1), it is in the off function (control element not pressed, contacts open).

- Slightly pressed (level 2), it switches to the enabling function (actuator pressed to middle position, contacts closed).

- If it is pressed further (level 3), it switches to the off function (forced opening of the contacts, actuator fully pressed beyond the middle position).

If it is released again in level 3, the switch returns to level 1 without closing the contacts during the transition. The two-level enabling switches thus lack level 3.

However, since a person tends to tense up more in panic or severe pain, i.e. to push through, and less to let go, this level 3 is of enormous importance for the safety of the operator and is therefore prescribed for new machines.

How does a three-stage enabling foot switch work?

The electromechanical design of an enabling foot switch is identical to that of the manually operated version. The difference is that the switching stages are logically operated with the foot.

Level 1 is also the rest position. In level 2, the operator presses the pedal of the foot switch up to the so-called pressure point (tactile resistance) to close the enabling contacts and release the machine movement. If the pedal is fully depressed beyond the middle position (level 3), the contacts open again.

So why does it make sense to use your foot?

The advantages of an enabling foot switch in contrast to a manually operated enabling device are not difficult to explain.

Especially in set-up operation, during a repair or while cleaning a machine, it is an advantage to have both hands available. Very often in these cases, the machine has to be moved through a step-by-step feed by means of stepping.

For example, the operator has both hands free when changing reels on a wire winding machine. Here, the wire of the newly inserted reel must be threaded and in the course of this, the machine moves at reduced speed and the release of the hazardous movement is given by pressing an enabling foot switch.

The machine operator thus has the possibility to bring the wire to the desired position with both hands after he has started the movement by means of a separate start control.

What are the advantages of BERNSTEIN foot switches with enabling function?

A major advantage of the BERNSTEIN foot switch is the position monitoring. From a control point of view, pedal positions 1 and 3 are completely identical. In both cases, the enabling contacts are open.

If you now want to evaluate the exact position of the pedal, this is not possible without aids. The BERNSTEIN enabling foot switches have an optional additional PNP signal output which indicates the exact pedal position.

It is also possible to use a so-called accident protection cover. This protects the foot switch from unintentional actuation and damage by falling parts. However, foot switches with accident protection covers are not approved for enabling operation for ergonomic reasons.

In addition, the enabling foot switches can be equipped with a safety latching mechanism. This ensures that the foot switch engages after reaching switch position 3 and that the machine cannot be started without first being unlocked.

Further areas of application for foot switches

Foot switches are often used as so-called “command devices with automatic reset” or “jog switches” for short, to set a machine to the operating state. Foot switches with enabling function are ideally suited for this purpose, as they meet very high safety requirements with the integrated approved enabling switch insert.

Further information on foot switches with enabling function and for inching mode can be found in our product catalogue.